-40%

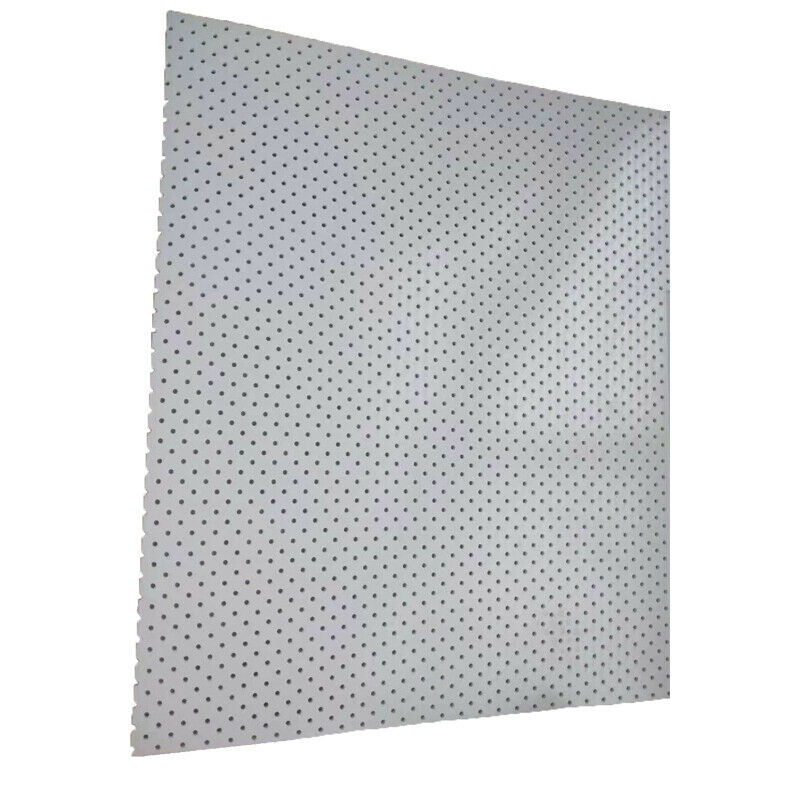

First Aid Injury Bone Fixation Thermoplastic Sheet Plate Plastic Splint Material

$ 70.21

- Description

- Size Guide

Description

First Aid Injury Bone Fixation Thermoplastic Sheet Plate Plastic Splint MaterialA thermoplastic splint is a device used to immobilize, protect and support injuries such as fractures, sprains and strains. Thermoplastic splints differ from traditional plaster casts in that they are lighter, easily molded to fit the body of the individual patient and can be removed for cleaning.

Size: 450*600*2.4 mm

Perforation: 5%

How to use?

Prepare the sheets and tools, adjust the water bath to 65-70 degree.

Pick up the right sheets as per different body part. (1.6mm thickness for nasal splints; 2.4mm for finger/hand splints; 3.2mm for arm, wrist, elbow , scoliosis splints, and neck splints, 4.0mm used for foot and leg splints. ).

Design a pre-cut on a paper, and cut the thermoplastic sheets with strong scissors accordingly.

Put the splint into water bath for 3-5 minutes, it could become soft and pliable.

Take the splint out and make it dry on a soft cloth, then place it on the paitent's body part.

Push the splint gentlely with fingers according to the trend of the user's bone, thus to make it form the right shape and angle.

It offers about 3 minutes time to fulfill the moulding work. As the temperature drops, the splint could become hard and rigid.

Decorate the splint with wrapping strap, if possible, try to make it personalized fit.

With a good memory, the above processes are allowed to repeat do and undo. That means during the whole treatment, the users just need one piece, thus to save money.

Features

:

1.

Water-resistant.

2.

Good memory.

3.

X-ray transculent.

4.

Avirulent, insipidity, permeability, no stimulate, no sticky, can be directly used on the skin.

5.

Eco-friendly. Auto-degraded under a certain condition

.